Manufacture of Z-ONA zeolite

The design of Z-ONA zeolite is based on several strategic considerations, such as selecting a zeolite type with broad market potential that can be synthesised using a simple process.

The MEDES group at IETcc-CSIC conducted a comprehensive laboratory-scale study to determine the variables in the Z-ONA zeolite manufacturing process from salt slag. The study examined how different experimental parameters (e.g. reaction temperature and time, reagent concentration, pH) affect the efficiency of the process and the type and quality of zeolite produced.

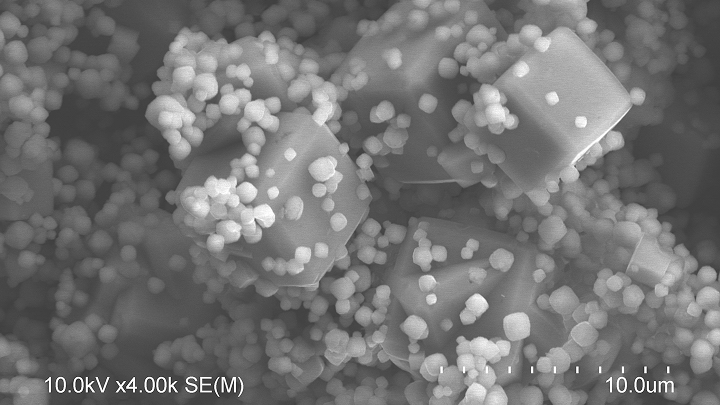

Microstructure of a zeolite produced from salt slag

The optimal synthesis parameters for scaling up to the pilot plant have been established and are being implemented in the construction of the Z-ONA zeolite manufacturing plant at the ALUSIGMA S.A. facilities.

Additionally, a study investigating the zeolite's chemical, mineralogical, and textural characteristics has revealed that it exhibits properties similar to natural zeolites, confirming its potential as an adsorbent in the purification of contaminated effluents.