The aluminium industry must find a definitive solution for the management of salt slag, included in the European Waste Catalog as hazardous waste, to improve its not yet perfected circularity. The EU produces 1 million tonnes of salt slag per year and its disposal is banned in most countries. Today, the management of salt slag is a global concern and its valorization is still not solved.

Z-ONA4LIFE foresees a holistic approach to salt slag recovery for the Circular Economy, the European Green Deal and the Sustainable Development Goals (SDGs). It focuses on a new circular zeolite (Z-ONA) production technology in its exploitation to overcome the problems associated with the purification of wastewater and gas streams. Zeolites will improve the environment in two ways: recovery of hazardous waste and purification of effluents. Z-ONA4LIFE considers salt slag as secondary raw material and creates an opportunity for the recovery of waste from other industries.

The use of Z-ONA is also planned for the purification of gas streams and wastewater (leachate, livestock and mining) in demonstration plants and real scenarios.

INDEREN, in collaboration with FERROSADIM, ALUSIGMA, and CSIC, will design, develop and start-up of a pilot plant for Z-ONA zeolite production.

Objectives:

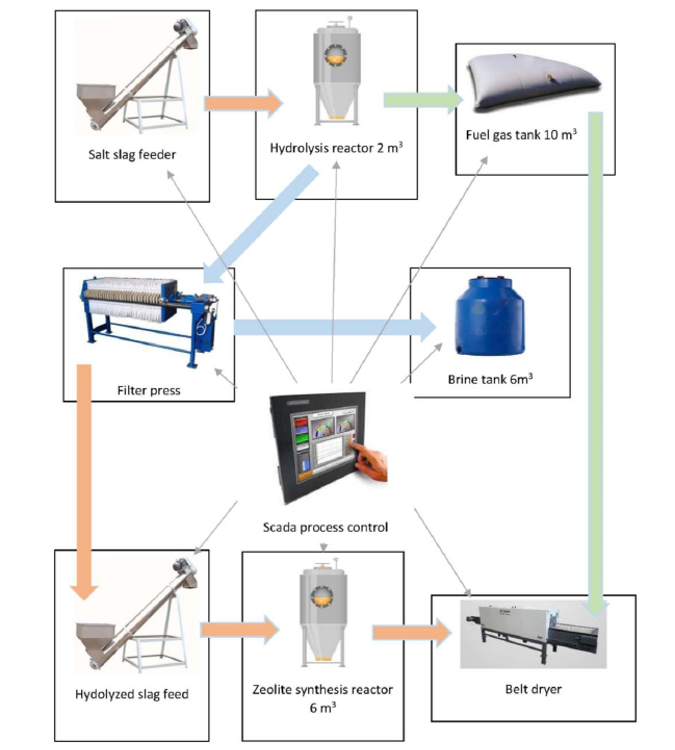

- Conceptual design of a pilot plant, including a hydrolysis reactor of 2000 L and a synthesis reactor of 6000 L.

- Start-up of a pilot plant to be used for both the hydrolysis of salt slag and the manufacturing of Z-ONA zeolite from the hydrolysed slag and Si-rich wastes.

- Pre-commercial production of zeolite in the pilot plant and its characterisation. A production of 220 t of Z-ONA zeolite throughout the entire project is estimated.

- Modelling of by-products recovery.

- Development will provide a functional pilot plant for Z-ONA zeolite production. Up to 628 kg of Z-ONA zeolite per day will be produced during the project lifetime from salt slag and Si-rich waste.

- The pilot plant for the production of Z-ONA zeolite will be installed in ALUSIGMA´s own facilities in Gijon, Asturias (Spain)

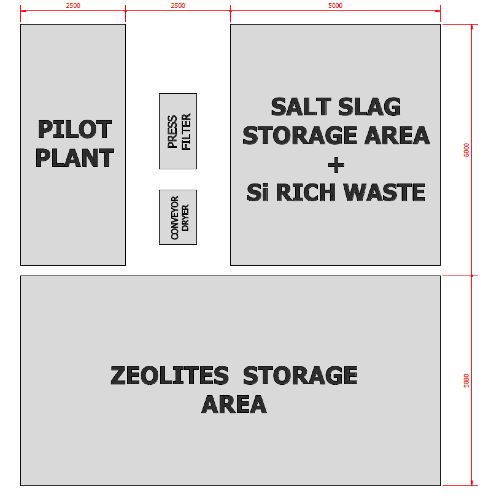

The dimensions of the roofed area destined to the pilot plant are 60 m long, 20 m wide, and 10 m high on the sides and 12 m high in the central area. It is the western wing (marked in red in the photograph) of the 5 wings or sections of ALUSIGMA´s pavilion. The space dedicated to the production of Z-ONE zeolite will cover a total area of 110 m2, including 30 m2 for the pilot plant installation, 30 m2 for raw material storage (hydrolysed slag and Si-rich waste), and 50 m2 for zeolite storage.

The distribution of the different working areas required for operating in the pilot plant, including the waste and zeolite storing, are shown in next figure.

The pilot plant will be built in different skid modules to facilitate road transportation to the Alusigma facilities.

Each skid will be grouped according to the final design to include all the equipment and elements that allow the synthesis of the salt slag output in the hydrolysis reactor and subsequent passage through the synthesis reactor where the formation of the zeolite will occur, which after filtering and drying will be It will have a granular material that is easily manipulated.

----------

Follow our social channels and subscribe to our newsletter in order to receive Z-ONA4LIFE updates and alerts about future events and webinars!