Advances in Salt Slag Treatment: Crucial Step Towards Sustainability

Part A: Conditioning of salt slag

In a significant milestone for the Z-ONA4LIFE project, important progress has been made in the first phase of the process, following the established schedule.

In the aluminum smelting process at ALUSIGMA's facilities, after casting the metal (See Figure 1), the dross (See Figure 2) is poured into containers for cooling (See Figure 3). Once the dross is cooled, it is bagged for subsequent treatment and management (See Figure 4).

The salt slag is sent to IETcc-CSIC in order to study the necessary conditions for pretreatment and to optimize the hydrolysis parameters. From a macroscopic perspective, the salt slag exhibits a heterogeneous nature, composed of particles of different sizes and shapes.

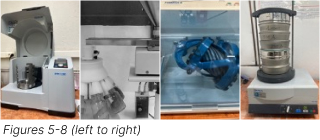

In the laboratories of the MEDES group at IETcc-CSIC, a series of tests are being carried out for the pretreatment of the slag. The first step is grinding (see Figure 5) and subsequent subdivision into representative fractions using an automatic sample splitter (see Figure 6). The homogenisation of the samples, a very important stage in the process, is carried out by means of a 3D mixer (See Figure 7).

Obtaining representative homogeneous samples is a critical aspect to minimise, as much as possible, heterogeneity and discrepancy in subsequent tests.

The salt slag is characterised through techniques such as X-ray fluorescence (XRF) and X-ray diffraction (XRD), in order to know its chemical and mineralogical composition. In addition, a granulometric classification study is carried out to analyze the phase distributions (chemical and mineralogical composition) in the different fractions (See Figure 8).

This process is carried out in a similar way for all silicon wastes covered by the Z-ONA4LIFE project.

-----

Part B: Hydrolysis of salt slag

In a pioneering advance towards the synthesis of sustainable materials, researchers from the Medes Group (IETcc-CSIC) have made significant progress in the hydrolysis of salt slags, a crucial step in the production of Z-ONA zeolite.

The use of salt slag in the production of Z-ONA zeolite is challenging due to its high salt content (sodium chloride, NaCl), which must be removed prior to its use as a raw material for Z-ONA synthesis. The aim of hydrolysis is precisely to remove this salt content.

The hydrolysis is carried out under strict safety measures in a fume hood to mitigate the risk of toxic gas emissions. A series of experiments are currently underway to determine the optimum conditions for the hydrolysis process (see Figure 1).

Once the hydrolysis process is completed, the hydrolysed slag, the gases generated and the resulting brine are thoroughly characterised. These data, fundamental for the progress of the Z-ONA4LIFE project, are being transferred to INDEREN for the design of the pilot plant for the scale production of Z-ONA zeolite.

The hydrolysed slag (see Figure 2) is destined for the next stage of the zeolite synthesis process.

This groundbreaking research not only promises to revolutionise zeolite production, but also underscores the commitment of scientific efforts to sustainability and environmental protection.

-----

Do you want to learn more about this process?

Read the main highlights from the first Z-ONA4LIFE Webinar that touched on this process and the overall ability of Z-ONA4LIFE to transform the aluminium industry, contributing to a greener and more resilient Europe.